Are American Security Safes Reliable? Expert Opinion

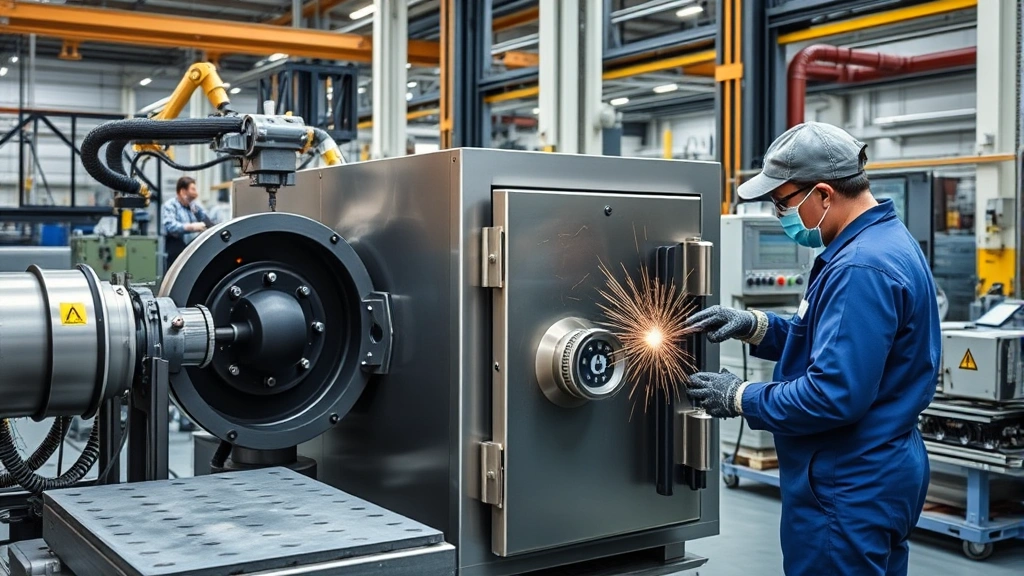

When protecting your most valuable assets—whether sensitive documents, cash, jewelry, or critical business records—the reliability of your security safe becomes paramount. American security safes have long been positioned as trusted solutions for asset protection, but the question remains: are they truly reliable? This comprehensive analysis examines the construction standards, security certifications, vulnerabilities, and expert assessments of American-manufactured safes to help you make an informed decision about your physical security infrastructure.

The market for security safes in the United States is substantial, with consumers and businesses investing billions annually in physical protection solutions. However, not all safes are created equal, and understanding the differences between manufacturers, construction methodologies, and certification standards is essential for anyone serious about asset protection. This guide explores what makes a safe genuinely reliable and whether American security safes meet those critical benchmarks.

Understanding Safe Construction Standards

The reliability of any security safe depends fundamentally on its construction quality and materials. American security safes vary significantly in their manufacturing approaches, from budget-friendly consumer models to enterprise-grade solutions designed to resist sophisticated attacks. The distinction between these categories directly impacts how reliably they protect your assets.

High-quality American security safes typically feature multiple layers of protection, including outer and inner steel shells with concrete or composite filling between them. This construction methodology makes drilling, cutting, or prying significantly more difficult than with thin-walled alternatives. The steel gauge, concrete density, and locking mechanism quality all contribute to overall reliability. Expert locksmiths and security professionals consistently note that safes with thicker steel walls and denser filling materials demonstrate superior resistance to common attack methods.

The door construction represents another critical reliability factor. Premium American safes employ multi-bolt locking systems with bolts that extend into the safe body at multiple points. When properly manufactured, these systems create redundancy—even if one bolt fails, others continue protecting the contents. Budget models often feature fewer bolts or weaker materials, substantially reducing their reliability against determined attackers.

Weight serves as an important indicator of safe construction quality. Heavier safes typically contain more steel and concrete, translating to better protection. However, weight alone doesn’t guarantee reliability; internal construction quality matters equally. A poorly designed heavy safe might still be vulnerable to sophisticated attacks, while a well-engineered lighter model could outperform it.

American Manufacturing vs. International Standards

American security safe manufacturers operate within a competitive domestic market that has driven innovation and quality improvements over decades. However, the United States does not mandate universal manufacturing standards for consumer security safes, creating a fragmented market where quality varies dramatically between producers. This lack of mandatory standardization represents a significant reliability concern for consumers.

In contrast, many European manufacturers operate under stricter regulatory frameworks. The British Standards Institution and similar organizations in other countries impose rigorous testing requirements. Some American manufacturers have voluntarily adopted these international standards, earning certifications that demonstrate their commitment to reliability. When evaluating American safes, checking for international certification compliance provides valuable assurance.

Domestic manufacturers range from established companies with century-long histories to newer entrants prioritizing profit margins over quality. The most reliable American security safes typically come from manufacturers who have invested heavily in testing facilities, quality control, and adherence to voluntary standards. These companies often publish detailed specifications and undergo third-party testing to validate their claims.

The manufacturing process itself impacts reliability significantly. American safes produced using precision machinery and rigorous quality control protocols perform better than those manufactured with minimal oversight. Some producers use automated welding systems that create stronger bonds than manual welding, while others rely on older techniques. Understanding a manufacturer’s production methodology helps assess safe reliability.

Certification and Testing Requirements

Several certification systems help identify genuinely reliable American security safes. The National Institute of Standards and Technology (NIST) provides guidelines for physical security, though these are not mandatory for consumer safe manufacturers. Nevertheless, manufacturers who voluntarily align their products with NIST recommendations demonstrate serious commitment to reliability.

The Underwriters Laboratories (UL) certification represents one of the most respected safety and security standards in North America. UL tests safes according to rigorous protocols involving resistance to drilling, prying, cutting, and other attack methods. Safes earning UL certification have demonstrated measurable reliability against specific threat vectors. However, not all American safes pursue UL certification, and this absence doesn’t automatically indicate poor quality—it may simply reflect manufacturer choice regarding certification investments.

The Builders Hardware Manufacturers Association (BHMA) provides additional standards for security hardware and mechanisms. Safes incorporating BHMA-certified locks benefit from components that have undergone independent testing. This modular approach to certification—where individual components meet established standards—contributes to overall safe reliability even when the complete safe hasn’t undergone full-system testing.

Time-rated certifications deserve special attention. Some safes carry ratings indicating how long they should resist attack under specific conditions—for example, “TL-30” means the safe should resist attack for at least 30 minutes using common tools. These time ratings, when issued by reputable testing organizations, provide concrete reliability benchmarks. American safes with verified time ratings offer substantially more protection than non-rated alternatives.

Third-party testing by independent security researchers adds another reliability indicator. When manufacturers submit safes to respected locksmiths or security consultants for evaluation, and those experts publish findings, you gain insight into real-world performance. Manufacturers confident in their products’ reliability often encourage such testing and publish results prominently.

Common Vulnerabilities in Security Safes

Understanding typical safe vulnerabilities helps assess reliability more effectively. Even well-manufactured American security safes can fail if they share common design weaknesses. Expert security consultants have identified several recurring issues affecting safe reliability across manufacturers.

Locking mechanism vulnerabilities represent a primary concern. Some safes feature locks susceptible to manipulation through techniques like lock picking or bypassing. The complexity and quality of the locking mechanism directly impact reliability. Safes using advanced electronic locks with anti-tampering features offer better protection than simple mechanical locks, though electronics introduce different vulnerabilities. The most reliable systems often combine mechanical and electronic security layers, creating redundancy.

Installation represents another critical reliability factor frequently overlooked by consumers. Even the best-manufactured safe provides minimal protection if installed improperly. A safe bolted to drywall instead of concrete foundation can be removed entirely, defeating all internal security features. Professional installation assessment ensures your safe’s reliability isn’t compromised by poor mounting.

Hinges and door seals sometimes present unexpected vulnerabilities. Lower-quality American safes may use hinges susceptible to prying or removal. The door seal quality affects both fire protection and burglary resistance. Gaps between the door and frame can allow tools to bypass locking mechanisms. Premium American safes feature recessed hinges and tight tolerances that eliminate these weaknesses.

Fire protection features, while important, sometimes compromise burglary protection. Safes optimized for fire resistance often use materials and designs that reduce resistance to drilling or cutting. The most reliable American safes balance both protections, though this balance varies. Understanding your primary threat—fire or theft—helps assess whether a particular safe’s design trade-offs align with your reliability needs.

Environmental factors including humidity, temperature fluctuations, and corrosion can degrade safe reliability over time. American safes intended for long-term reliability should include corrosion-resistant materials and proper ventilation to prevent internal rust. Safes stored in damp environments require additional protective measures to maintain reliability.

Expert Assessment of American Safes

Professional locksmiths, security consultants, and manufacturers provide valuable insights into American safe reliability. These experts, who interact with safes across various conditions and applications, offer practical perspectives beyond marketing claims. Their assessments reveal consistent patterns regarding which American safes perform reliably and which disappoint in real-world conditions.

Established manufacturers with multi-decade histories generally produce more reliable products than newer competitors. Companies that have survived competitive markets for 50+ years typically maintain quality standards necessary for long-term reputation. However, longevity alone doesn’t guarantee current product reliability; some historic manufacturers have reduced quality standards in recent years to compete on price.

Security professionals consistently recommend American safes from manufacturers who publish detailed specifications, undergo independent testing, and maintain transparent quality control processes. Manufacturers willing to answer technical questions about construction materials, testing protocols, and design rationale demonstrate confidence in their products’ reliability. Those deflecting such inquiries may be hiding quality compromises.

The Cybersecurity and Infrastructure Security Agency (CISA) provides resources about physical security that complement safe selection guidance. While primarily focused on cyber threats, CISA acknowledges that physical security of sensitive equipment and documents remains critical to overall security infrastructure. Their recommendations align with selecting safes from manufacturers demonstrating genuine reliability commitments.

Expert reviews from independent security researchers provide particularly valuable reliability assessments. When respected professionals publish detailed analyses of how specific American safe models perform against various attack methods, you gain concrete data about real-world reliability. Such reviews often reveal vulnerabilities manufacturers downplay and strengths that justify premium pricing.

Insurance company requirements offer another reliability indicator. Insurers, motivated by financial interest in loss prevention, often specify safe requirements for coverage. Policies requiring safes from particular manufacturers or with specific certifications reflect insurance industry assessment of reliability. Meeting insurer requirements typically ensures adequate protection for most applications.

Choosing a Reliable Safe for Your Needs

Selecting a genuinely reliable American security safe requires evaluating multiple factors beyond brand reputation. Your specific needs—what you’re protecting, from what threats, and for how long—should drive your selection process. A safe perfectly reliable for one application might be inadequate for another.

First, identify your primary threats. Are you protecting against theft, fire, or both? Do you face casual burglars or sophisticated attackers? Is your concern recent valuable items or long-term document preservation? Your threat assessment determines which reliability factors matter most. A safe reliable against fire damage might be inadequate against determined theft, and vice versa.

Next, establish your budget realistically. Reliability correlates strongly with price, but not in a simple linear relationship. Spending $500 versus $1,000 might yield substantial reliability improvements, while spending $5,000 versus $10,000 might provide marginal gains. Identify the price point offering reliability appropriate for your threat level and asset value.

Research manufacturer backgrounds thoroughly. Established American manufacturers with transparent quality information, published certifications, and accessible customer references offer better reliability assurance than lesser-known producers. Check whether manufacturers provide detailed specifications about steel gauge, concrete composition, bolt systems, and testing results.

Verify certifications independently. Don’t rely solely on manufacturer claims about UL certification or time ratings. Confirm certifications through official sources. A safe claiming “UL approved” without specific certification numbers should raise reliability concerns. Legitimate certifications include verifiable details and testing reports.

Consider professional installation. Even the most reliable American safe provides inadequate protection if installed improperly. Budget for professional installation by qualified technicians who understand proper anchoring, positioning, and integration with your overall security system. Poor installation substantially undermines safe reliability.

Read customer reviews and professional assessments carefully. Focus on reliability-related feedback—how well the safe actually protects contents, whether mechanisms function reliably long-term, and how the manufacturer responds to problems. Discount reviews emphasizing aesthetics or convenience; prioritize those discussing security performance.

FAQ

What makes American security safes different from imported models?

American safes vary in quality based on manufacturer standards rather than origin alone. Some American manufacturers produce world-class reliable safes exceeding international standards, while others produce lower-quality models. Similarly, some imported safes meet rigorous standards while others don’t. The manufacturer’s commitment to quality matters more than national origin. Look for specific certifications and test results rather than relying on where the safe was manufactured.

How long should a reliable American security safe last?

Well-manufactured American safes from quality producers can function reliably for 20-30+ years with proper maintenance. However, reliability depends on storage conditions, usage frequency, and how well you maintain the mechanisms. Regular inspection, proper lubrication of moving parts, and environmental control extend safe reliability significantly. Poorly made safes might fail in 5-10 years regardless of intended lifespan.

Are electronic locks more reliable than mechanical locks in safes?

This question lacks a simple answer. Electronic locks offer convenience and sophisticated security features but introduce vulnerability to electronic attacks or battery failure. Mechanical locks provide reliable security without electronic dependencies but are sometimes vulnerable to picking. The most reliable safes often combine both systems, creating redundancy. Your reliability needs determine which locking system suits you best.

Can I improve my American safe’s reliability after purchase?

You can enhance reliability somewhat through proper installation, regular maintenance, and environmental control. However, fundamental design limitations can’t be overcome after manufacturing. A poorly designed safe won’t become reliable through upgrades. Focus on proper installation in a secure location, regular mechanism maintenance, and environmental controls to preserve your safe’s inherent reliability.

What should I look for in manufacturer specifications to assess reliability?

Reliable manufacturers provide detailed information about steel gauge, concrete composition, bolt quantity and extension distance, locking mechanism specifications, and independent testing results. They should clearly state certifications with reference numbers and explain design choices. Vague specifications or resistance to technical questions suggest reliability concerns.

How does price correlate with American safe reliability?

Generally, higher prices indicate better materials and construction, but correlation isn’t perfect. A $2,000 safe from a quality manufacturer is typically far more reliable than a $500 model, but spending $10,000 doesn’t guarantee proportionally better reliability than $5,000. Research specific models rather than assuming price automatically indicates reliability. Sometimes mid-range safes offer excellent reliability-to-cost ratios.

Should I choose a safe with fire ratings if I’m primarily concerned about theft?

Fire-resistant safes sometimes compromise burglary resistance through design trade-offs. If theft is your primary concern, prioritize safes optimized for burglary protection even if fire ratings are lower. If you need both protections, ensure the safe balances both rather than optimizing for one at the expense of the other. Your primary threat should drive your selection.